Low-cost nanoparticles for use across diverse industries

- Biology

Biotechnological processes have relied on nanoparticles to detect, capture, carry and purify biological and chemical products for decades. While these nanoparticles have been (mostly) fit for purpose, one researcher believes there’s room for improvement.

Traditionally, biotech researchers have used nanoparticles made of gold, silica, iron oxide, polymers or liposomes (fatty capsules – often containing drugs or other substances) for imaging, targeted drug delivery and bioseparation – the use of cells, proteins and other biological components to separate parts of a mixture.

While none are harmful or toxic to living tissue – i.e. they’re biocompatible – only polymer-based nanoparticles and liposomes are biodegradable. Furthermore, materials such as gold are expensive and costs pile up in isolation and functionalisation (attachment of functional proteins or other components) processes.

Additionally, polymer-based nanoparticles require time-consuming cross-linking reactions to attach functional proteins to their surface. However, residues left over from cross-linking reactions could lead to unpredictable, adverse side effects if used inside the body.

Similarly, most methods for functionalising liposomes are nonspecific and can lead to uncontrolled bonding between the liposome and the functional protein. Furthermore, in cases where lipids (fatty acids or related molecules) are used to attach functional units to the liposome, there’s the potential for uncontrolled reactions between the lipid and other components of the liposome – including the encapsulated drugs.

As a result, Professor Xiaoyun Lu of Xi’an Jiaotong University and her team have been working to develop an efficient and low-cost platform for creating functional nanoparticles that are biocompatible, biodegradable and are able to bond reliably without affecting the functional proteins or drugs.

The researchers have created a powerful, low-cost platform for generating functional nanoparticles.

Nanoparticles: the new generation

Instead of using traditional materials, Professor Lu and her team have opted to create their nanoparticles out of polyhydroxyalkanoates (PHAs). PHAs are a family of biopolyesters produced by bacteria to store carbon and energy – similar to fat in humans. Like human fat, they are produced in times of excess ‘food’, or carbon, and used by the ‘body’, or cell, when nutrients are scarce.

Also like fats, PHAs are insoluble in water and, instead, form granules approximately 50–500 nanometres (nm) in diameter. In nature, they’re encapsulated by a membrane containing granule-associated proteins, such as PHA synthase (PhaC), PHA depolymerase (PhaZ) and PHA granule binding protein (PhaP). These granule-associated proteins build-up or break-down PHA depending on the microbe’s needs.

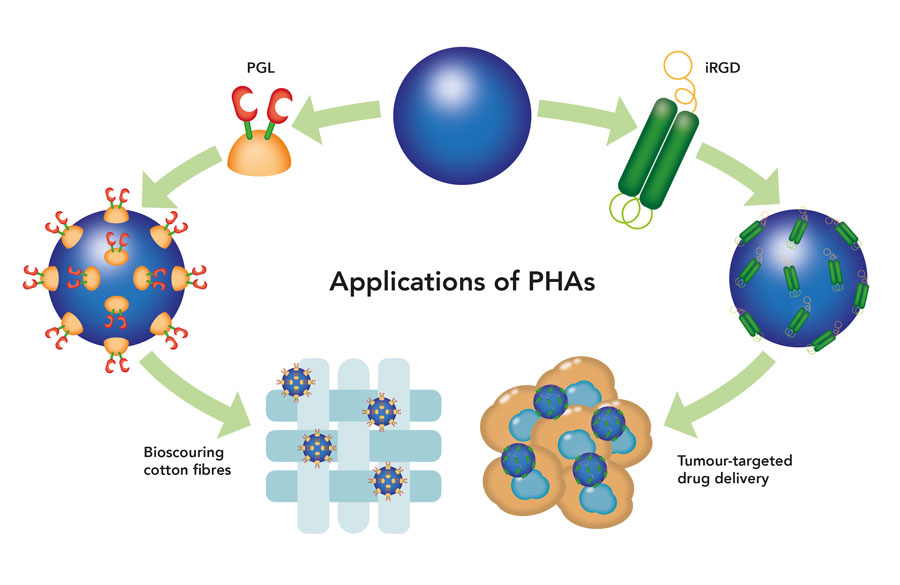

As a result, PHAs are inherently biocompatible and biodegradable and their formulation by bacteria means they can be quickly and easily generated at high-volume and low-cost. Furthermore, genetically engineered bacteria can also produce functional proteins and fuse them to PHAs’ granule associated proteins, removing the need for cross-linking reactions and reducing the risk of random bonding with or hinderance of the functional units. Finally, PHA nanoparticles can be easily purified by breaking open the cells and centrifuging the contents. These combined qualities make PHAs ideal for use in a variety of industries. Over the past three years, Professor Lu and her team have successfully demonstrated their use in bioseparation and as vessels for targeted anticancer drug delivery in mice.

A mean, green, cleaning machine

Conventional separation methods, known as scouring, often use harsh, alkaline (basic) chemicals and large amounts of energy, leading to environmental pollution and inefficient use of resources. By replacing these harsh chemicals with biological components – such as proteins and enzymes (proteins that facilitate biochemical reactions) – scouring can become a much cleaner and more environmentally-friendly process.

Enter Professor Lu’s nanoparticle and a functional protein (enzyme) called polygalacturonate lyase (PGL). PGL is already widely used for bioscouring cotton fibres (removing impurities from the fabric) and biodegumming plant fibres due to its ability to withstand high pH environments and high temperatures. However, capturing and purifying the enzyme is often expensive and labour intensive. Moreover, they’re often attached by cross-linking which can lead to loss of function or – if not properly attached – loss of the enzyme entirely.

Seeing this, Professor Lu and her team sought to attach PGL to their PHA nanoparticle by fusing it to PhaC in genetically modified bacteria. This fusion not only allowed the enzyme to maintain its function, but also allowed it to be reused at least seven times after the initial round of bioscouring – thus reducing costs and increasing sustainability. It even holds the enzyme in the right orientation to effectively bind and break down the fabric’s impurities.

Better still, the support offered by the PHA nanoparticle allowed PGL to remain active at suboptimal temperatures and pH conditions, making it highly likely that they’ll be able to withstand harsher, industrial bioscouring conditions which occur at pH 9 and temperatures from 40–60°C. In the future, Professor Lu hopes that the optimisation and application of PGL and functionalisation of PHA nanobeads with a variety of enzymes will lead to commercialisation of environmentally-friendly alternatives to existing industrial processes.

PHAs are a family of biopolyesters produced by bacteria to store carbon and energy – similar to fat in humans.

Homing in on cancer

For decades, researchers have attempted to combat solid tumours with polymer-based nanoparticles carrying anticancer drugs due to their biodegradability and capacity for controlled drug release. However, the potential adverse effects of residues from cross-linking reactions connecting nanoparticles and functional proteins limited their use. Moreover, the high tissue density and fluid pressure of tumours have prevented nanoparticles from getting inside the mass to deliver the drugs.

Instead, researchers, such as Professor Lu, have begun to look to PHAs to do the job. In her 2018 study, Professor Lu attached the artificial tumour-homing peptide, iRGD to PHA using PhaP as a special protein linker. Thanks to iRGD’s strong ‘nose’ for tumours and ability to penetrate the dense tumour tissue, anticancer-drug-carrying PHA nanoparticles were able to infiltrate even the deepest parts of the masses. Meanwhile the added stability provided by PhaP helped the iRGD modified PHA nanoparticles withstand the acidic environment inside the tumour.

This combination allowed the nanoparticles to accumulate within the masses in high concentrations so that drugs could be delivered continuously over long periods. Similar results were seen in Professor Lu’s earlier study, where she fused an epidermal growth factor receptor (EGFR)-targeting peptide (ETP) to the nanoparticle via PhaP. EGFR is known to be overexpressed in a variety of human cancers, making it a perfect target for anticancer drug delivery.

When equipped with ETP, PHA nanoparticles successfully targeted tumours with high efficiency, both in vitro and in mice. In fact, fluorescence imaging 24 hours post-injection with the ETP nanoparticles showed high levels of accumulation and retention in the tumours, despite some being filtered to the liver. With further refinement, we could one day see functionalised PHA nanoparticles used for targeted drug delivery in humans.

To date, PHAs have been successfully commercialised as mulches for agriculture and sutures for surgery based on their excellent biodegradability and biocompatibility. Currently, scientists are committed to developing PHAs as a variety of tissue engineering scaffolds, such as nerve catheters, endovascular stents, artificial oesophagus, heart valve replacement stents and bone/cartilage repair stents. It is also a research hotspot to endow these biopolyesters with special functions (pH response, temperature sensitivity, piezoelectric properties, etc.) by regulating the diversity of PHA structures. I believe that the above PHA products will gradually meet with consumers in the next decade or so.

What are your future plans for research in this area?

Our group is now trying to immobilise a precious epimerase on the surface of PHA beads, which is able to convert fructose into psicose at a very low cost. Since it has almost zero calories, psicose is the most potential alternative to sucrose, helping to fight obesity and diabetes. In addition, a small molecule antineoplastic drug, which failed to pass Phase II clinical trial due to poor bioavailability, was encapsulated in PHA nanoparticles modified by both iRGD and ETP. Enhanced bioavailability and anti-tumour effect of this targeted drug delivery system is being evaluated in multiple tumor models.

References

- Fan, F., Wang, L., Ouyang, Z., Wen, Y., et al. (2018). Development and optimization of a tumor targeting system based on microbial synthesized PHA biopolymers and PhaP mediated functional modification. Applied Microbiology and Biotechnology, [online] 102(7), 3229–3241. Available at: https://link.springer.com/article/10.1007%2Fs00253-018-8790-2 [Accessed 20.12.18].

- Fan, F., Wu, X., Zhao, J., Ran, G., et al. (2018). A Specific Drug Delivery System for Targeted Accumulation and Tissue Penetration in Prostate Tumors Based on Microbially Synthesized PHBHHx Biopolyester and iRGD Peptide Fused PhaP. Applied Bio Materials, [online] 1(6), 2041-2053. Available at: https://pubs.acs.org/doi/10.1021/acsabm.8b00524 [Accessed 20.12.18].

- Ran, G., Tan, D., Dai, W., et al. (2017). Immobilization of alkaline polygalacturonate lyase from Bacillus subtilis on the surface of bacterial polyhydroxyalkanoate nano-granules. Applied Microbiology and Biotechnology, [online] 101(8), 3247–3258. Available at: https://link.springer.com/article/10.1007%2Fs00253-016-8085-4 [Accessed 20.12.18].

- Perkins, R. (2016). Here’s a way to produce nanomaterials on a larger scale [online] USCNews. Available at: https://news.usc.edu/92312/heres-a-way-to-produce-nanomaterials-on-a-larger-scale/ [Accessed 20.18.2018].

- Salata, O. (2004). Applications of nanoparticles in biology and medicine. Journal of Nanobiotechnology, [online] 2(3). Available at: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC419715/ [Accessed 20.12.18].

- Wang, E., and Wang, A. (2014). Nanoparticles and their applications in cell and molecular biology. Integrated Biology, [online] 6(1), 9-26. Available at: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3865110/ [Accessed 20.12.18].

- Vabbilisetty, P. and Sun, X. (2014). Liposome Surface Functionalization Based on Different Anchoring Lipids via Staudinger Ligation. Organic Biomolecular Chemistry, [online] 12(8), 1237–1244. Available at: http://europepmc.org/backend/ptpmcrender.fcgi?accid=PMC3955738&blobtype=pdf [Accessed 20.12.18].

- Zanoni, M., Habimana, O., Amadio, J., Casey, E. (2015). Antifouling activity of enzyme-functionalized silica nanobeads. Biotechnology and Bioengineering, [online] 113(3), 501-512. Available at: https://onlinelibrary.wiley.com/doi/full/10.1002/bit.25835 [Accessed: 20.12.18].

Prof Lu and her team have created a platform to generate functionalised biodegradable polyhydroxyalkanoate nanoparticles.

Funding

We would like to acknowledge the financial support from:

- The National Natural Science Foundation of China (Nos. 81172170, 81371288 and 21306110), and

- Fundamental Research Funds for the Central Universities from Xi’an Jiaotong University.

Collaborators

- Prof Guoqiang Chen, (Tsinghua University)

- Lecturer Dan Tan, (Xi’an Jiaotong University)

Bio

Dr Xiaoyun Lu is a Professor of biochemistry and molecular biology at School of Life Science and Technology, Xi’an Jiaotong University. She is the author of more than 50 publications and funded by six national projects. She has made several important contributions in applications of functionalised biodegradable polyhydroxyalkanoate biopolymers.

Dr Xiaoyun Lu is a Professor of biochemistry and molecular biology at School of Life Science and Technology, Xi’an Jiaotong University. She is the author of more than 50 publications and funded by six national projects. She has made several important contributions in applications of functionalised biodegradable polyhydroxyalkanoate biopolymers.

Contact

Professor Xiaoyun Lu

Xi’an Jiaotong University

No.28, Xianning West Road, Xi’an, Shaanxi, 710049, P.R. China

E: [email protected]

T: +86 1535 371 3886

W: http://en.xjtu.edu.cn/

W: http://gr.xjtu.edu.cn/web/luxy05/5

W: http://slst.xjtu.edu.cn/

Creative Commons Licence

(CC BY-NC-ND 4.0) This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. Creative Commons License

What does this mean?

Share: You can copy and redistribute the material in any medium or format

Investigation of mathematics teaching and learning in China