By 2025, more than one third of the world’s population may need to consume plant-based meat alternatives to meet soaring demand for protein. Currently, methylcellulose (MC) is used as a cost-effective binder in most commercial plant-based meat alternatives. However, MC is also the main ingredient in many laxatives – prompting researchers to look for alternative, chemical-free binding systems. Dr Kiyota Sakai and colleagues at Amano Enzyme Inc have developed a new way of crosslinking proteins with sugar beet pectin in meat analogue patties: tantalisingly improving texture, firmness, and juiciness without chemicals.

Meat consumption is at an all-time high. In line with an ever-increasing global population, which is set to reach 9.7 billion by 2050, the demand for meat around the world has increased by 58% in the last two decades. While this demand is expected to rise steadily, limited land and water resources, undesirable effects on the environment due to farming, and concerns around animal welfare pose serious challenges that will threaten the supply of dietary protein for future generations. According to estimates by the United Nations, after decades of steady decline, the number of people who suffer from malnourishment began to slowly increase again in 2015. Increasing agricultural productivity and sustainable food production is crucial to alleviate the threat posed by hunger and malnutrition. Many scientists argue that to fill the gap between present supply and future demand of meat, plant-based alternatives as protein sources will be needed. Dr Kiyota Sakai and his colleagues at Amano Enzyme Inc are actively finding new ways of helping this happen.

New texture-enhancing binding system

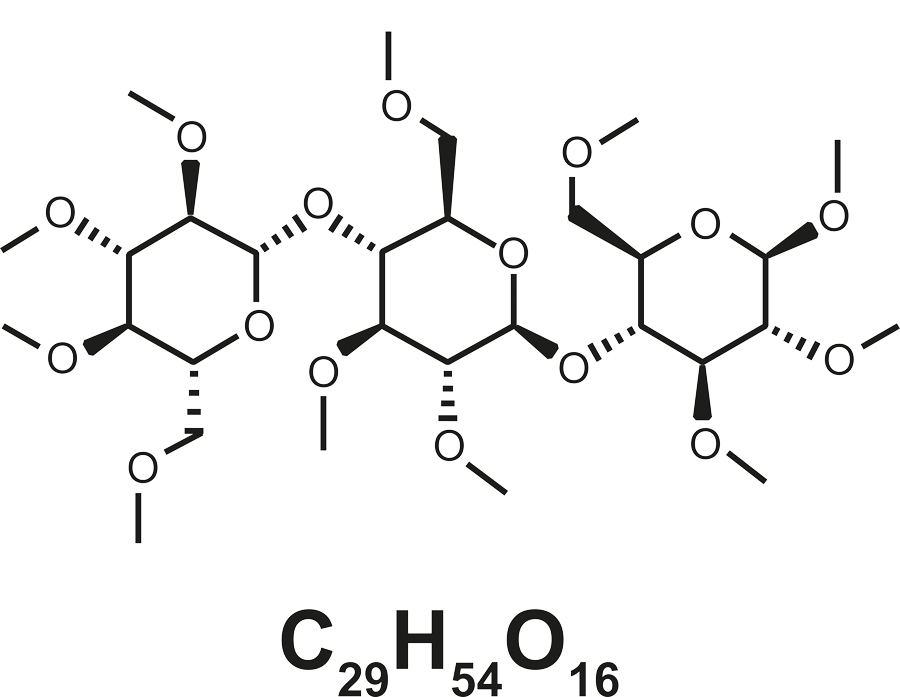

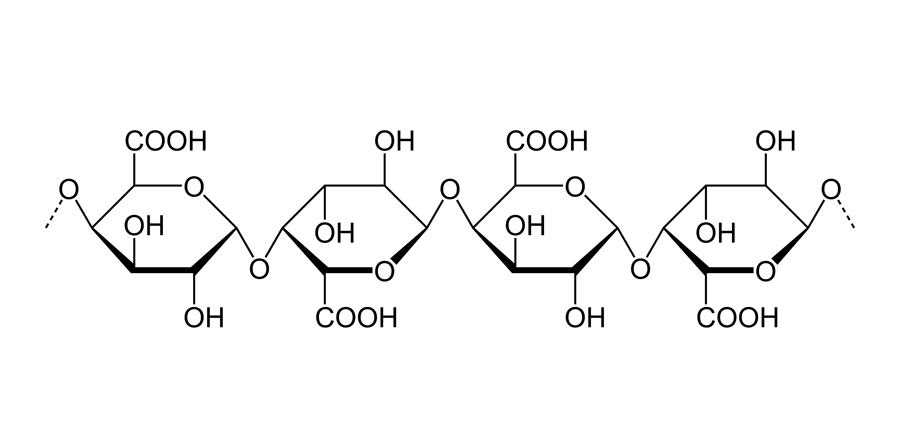

Current meat alternatives consist mainly of textured vegetable proteins (TVPs) that imitate the fibrillar structure of meat muscle. TVPs, including soy-based TVP, can also mimic the taste, smell, texture, and appearance of red meat, while at the same time providing a dietary alternative that is cholesterol-free, with low concentrations of saturated fat and high concentrations of essential amino acids. Unlike animal proteins, TVPs do not possess the same binding abilities, so meat analogue manufacturers use binders to improve the texture of the final product. Methylcellulose (MC) is used as a binder in most commercial products because of its low cost. Although MC is considered safe for human consumption, it’s also the main ingredient in many laxatives, prompting researchers to look for alternative systems.

Natural catalysts

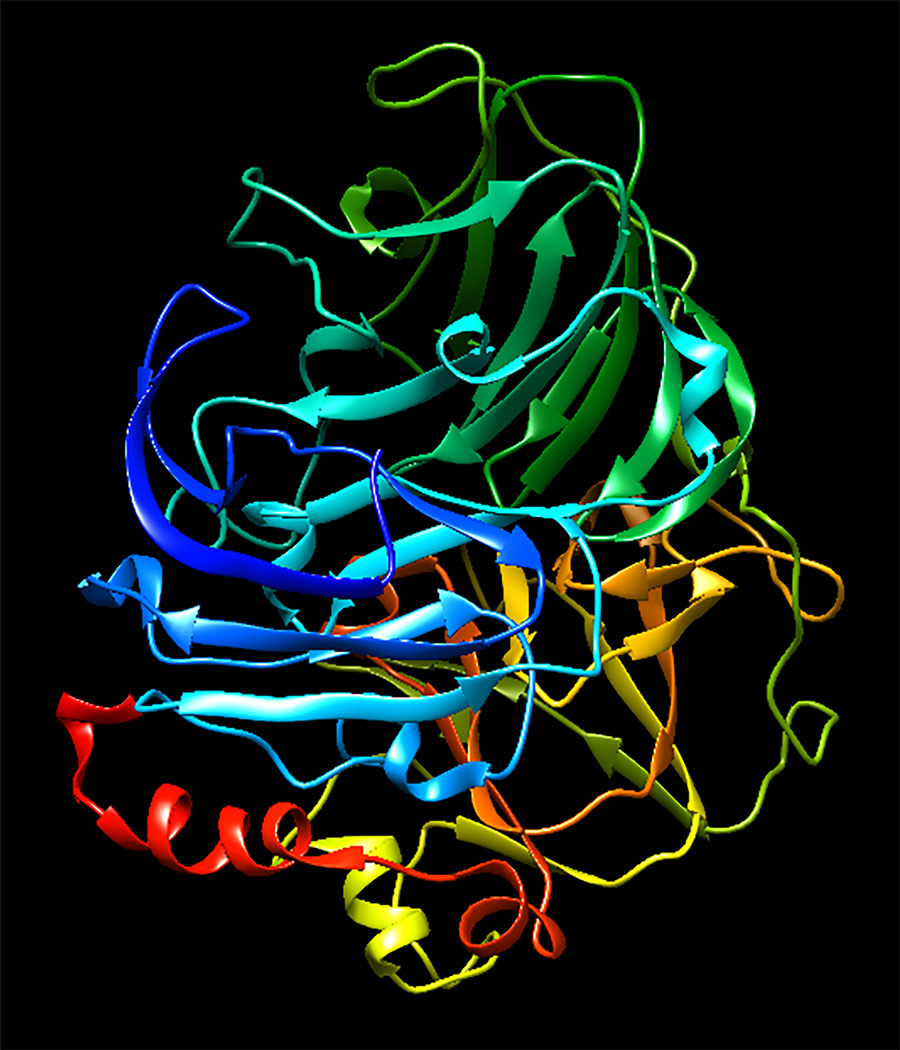

Sakai and his colleagues set out to develop a new chemical-free binding system for meat analogues. To achieve this, they aimed to exploit the ability of a natural enzyme. Enzymes are biological molecules, often proteins, which act as natural catalysts, facilitating chemical reactions that would not occur spontaneously at a fast enough rate to support biological processes. Essential for metabolic processes to proceed, enzymes exert their action on smaller molecules known as substrates, facilitating their conversion into products.

“To fill the gap between present supply and future demand of meat, plant-based alternatives as protein sources will be needed.”

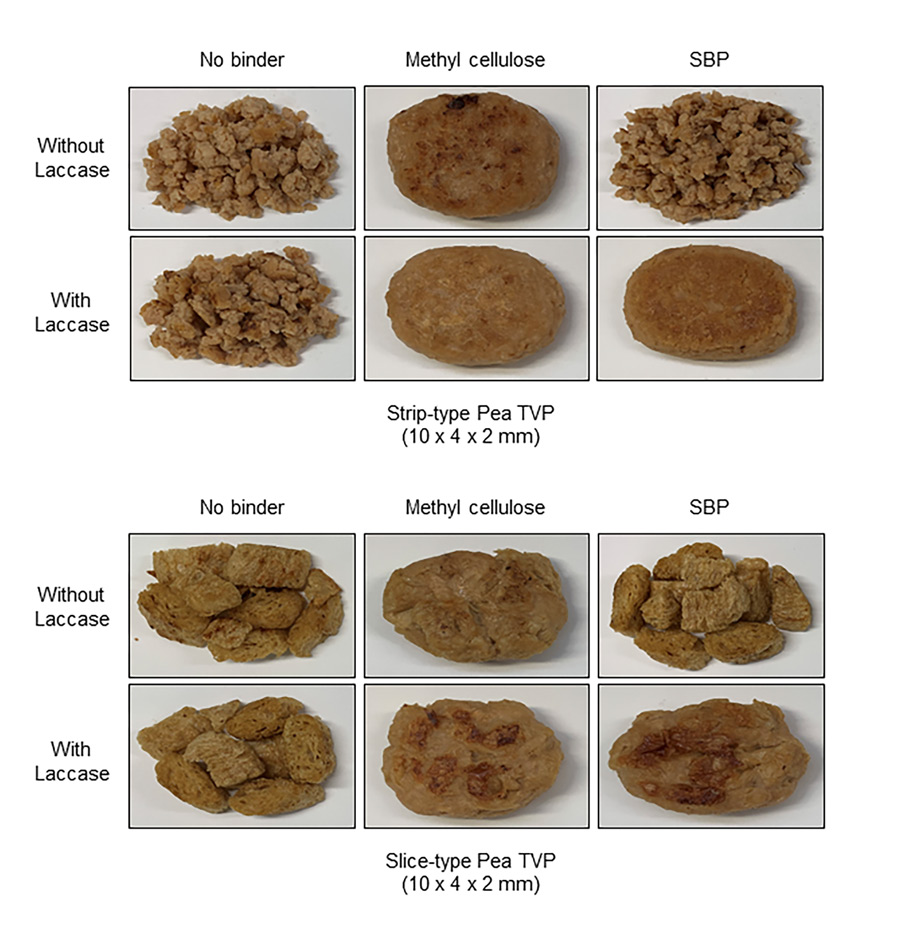

In a recent study, Sakai reports the development of a novel chemical-free binding system, based on the ability of the natural enzyme laccase (LC). This enzyme can introduce crosslinks between TVPs and sugar beet pectin (SBP). Sakai demonstrated that SBP can be used as a mediator to enable the LC enzyme to crosslink protein-based foods, acting as a novel binding agent in the manufacture of plant-based protein sources. Exploiting this ability of forming crosslinks within proteins, his method improves the physical, chemical, and nutritional properties of meat analogues.

The innovative inclusion of LC and SBP in the preparation of meat analogue patties results in a wide array of enhanced properties. The study reveals that LC-treated meat analogue patties possess improved binding abilities and mouldability, maintaining their shape after grilling. The treatment also increases the water and oil holding capacity of the patties, an important factor that improves the juiciness of the meat analogues. Advantages of treating TVPs with LC and SBP were not limited to only improved taste and texture. Generally, the protein content from meat analogues is not absorbed by the body as easily as animal-derived proteins. However, the researchers showed that their method improved the digestion of meat analogues. Based on the study’s results, this method offers great promise to increase the nutritional value of meat analogue patties when compared with standard plant-based meat analogues.

Turning to meat-free alternatives

There are several driving forces at play behind the development of meat alternatives. Some of the strongest arise from environmental, health, and animal welfare concerns associated with meat production. Meat production processes are less energy-efficient than the growth and harvesting of plants, despite the technological advances aimed at increasing production efficiency. The maintenance of livestock requires extensive land use and a considerable amount of fossil fuels to power the farm facilities. It has been demonstrated that even a partial replacement of meat with plant-based proteins can significantly reduce land use and emission of greenhouse gases.

The World Health Organization recently reported that the consumption of processed meat (such as smoked meat, ham, bacon, and sausages), as well as red meat products (such as beef, lamb, and pork), has been linked to cancer. Furthermore, the presence of saturated fatty acids in red meat is linked to higher risk of cardiovascular disease due to an increased incidence of low-density lipoproteins in the body. A large body of research has revealed the health benefits associated with switching animal sources of protein with plant-based sources, including reduced risks of type 2 diabetes, heart disease, and stroke. Furthermore, meat analogues are rich in dietary fibre, which plays an essential role in preventing bowel disease, heart disease, and diabetes.

“Sakai’s research allows manufacturers to improve the texture, firmness, and juiciness of meat alternatives – crucial qualities for consumers’ satisfaction.”

As consumers have become increasingly aware of the treatment and lifestyle of livestock, many hold serious concerns for the overall health and welfare of farmed animals. Problems are increasingly arising from poor farm management practices, including livestock being subjected to beatings and animal health issues that are left untreated by farmers. Intensive farming systems are similarly contentious, where livestock are reared in extremely high densities, which result in elevated levels of stress and an increased risk of diseases amongst the animals. As such, more people than ever before are looking at meat-free alternatives for sources of dietary protein.

Zero Hunger by 2030

According to the United Nations World Food Programme, 135 million suffer from acute hunger – largely due to man-made conflicts, climate change, economic downturn, and the COVID-19 pandemic. Although a radical change of the global food and agriculture system is needed to sustain the increasing world population, the UN forecasts that the world is not on track to meet its Sustainable Development Goal 2: Zero Hunger by 2030. In fact, if current trends continue, the number of people affected by hunger will surpass 840 million by 2030, or 9.8% of the global population. One way to make the goal more achievable is to switch to plant-based diets.

Although replacing meat in our diet with meat alternatives can provide a wide range of health and environmental benefits, most consumers remain unwilling to eliminate animal products from their diet. However, Sakai’s research allows manufacturers to improve the texture, firmness, and juiciness of meat alternatives – crucial qualities for consumers’ satisfaction and acceptance of food products.

Furthermore, the method proposed by Sakai and his collaborators is the first chemical-free binding system for meat analogues. The novel method of production is associated with considerable health benefits, including a 2.3-fold higher release of free amino nitrogen after gastrointestinal digestion, compared to that released from meat analogues treated with MC as the binder. With this new method for manufacturing more delicious and nutritious plant-based protein sources, more people will reap the benefits of a meat-free or reduced meat diet – whilst also helping to lessen the impact of human agriculture on our world’s fragile ecosystem.

Using enzymatic methods, we aim to solve the technical challenges faced by customers and manufacturers of plant-based foods, especially meat and milk alternatives. In a recent study, we tackled one of the challenges of plant-based meat analogues using enzymatic methods. We safely and effectively imitated the colour of meat alternatives, which is important for the perception of taste and overall product acceptance: www.nature.com/articles/s41598-022-05091-4. In this way, I would like to maximise the potential of enzymes.

References

- Sakai, K, Sato, Y, Okada, M, Yamagutchi, S, (2021) Improved functional properties of meat analogs by laccase catalyzed protein and pectin crosslinks. Scientific Reports, 11, 16631. doi.org/10.1038/s41598-021-96058-4.

- He, J, Evans, N, Liu, H, Shao, S, (2020) A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Comprehensive Reviews in Food Science and Food Safety, 19 (5), 2639–2656. doi.org/10.1111/1541-4337.12610.

- The United Nations (2020). Goal 2: Zero Hunger [online]. The United Nations. Available at: www.un.org/sustainabledevelopment/hunger/ [Accessed 08/02/2022].

10.26904/RF-140-2389701088

Research Objectives

Using enzyme technology, Kiyota Sakai develops innovative plant-based alternative foods.

Bio

Dr Kiyota Sakai completed his studies at Meijo University between 2012 to 2018. He then joined Amano Enzyme Inc, where he specialises in enzyme technology for developing plant-based alternative foods.

Contact

1–6 Technoplaza

Kakamigahara-Shi

Gifu, 509-0109

Japan

E: kiyota_sakai@amano-enzyme.com

T: +81 (0)58 379 1223

W: www.amano-enzyme.co.jp

W: www.amano-enzyme.com/uk