- Securing clean, sustainable water and energy supplies is a critical issue worldwide.

- Wastewater treatment plants currently rely on energy-heavy processes to help microbes digest organic matter.

- Professor Fabian Fischer and his team at HES-SO in Switzerland use electrogenic bacteria in microbial fuel cells (MFCs) to convert energy from sewage into electricity.

- The team has successfully upscaled previous work to produce a 1,000-litre MFC, which could significantly reduce treatment plants’ energy consumption and operating costs.

- They believe MFCs have potential to power many everyday electronic items in remote locations and areas without infrastructure.

Keeping the world supplied with clean water is an expensive business, currently relying on processes that consume large amounts of energy. But what if we could harness natural sources of electricity to make the process more efficient?

Bioelectricity occurs when living things acquire energy from organic sources and convert it into an electrical output. Common examples include the bioluminescence produced by fireflies to attract a mate during a summer night, or the discharge used by electric eels to stun their prey. As well as these visible phenomena, many microorganisms can also generate bioelectricity, but in such minuscule amounts that a large microbial colony is needed before their output can be measured. For several years, a team led by Professor Fabian Fischer at HES-SO Valais, Switzerland, has been investigating the potential of microbial fuel cells (MFCs), which use cultured electrogenic bacteria to generate bioelectricity.

Water supply and wastewater purification consume 1–2% of Switzerland’s electricity output. The team came up with their method of harnessing the electrical energy produced by MFCs to minimise the costs and energy expenditure of wastewater treatment plants. While the electrogenic microbes also require aeration to thrive, their metabolic activity would result in the net production of useful electrical energy that could be used to cover, at least in part, the energy requirements of the water treatment plant. The researchers maintain that, if properly harnessed, the electricity from microbial fuel cells could also be used to charge batteries for cars, computers, and other electronic devices, as well as saving energy for wastewater operators today.

The researchers started their venture by originally designing small prototype reactors that ranged from 20 to 250 ml.

A simple and innovative concept

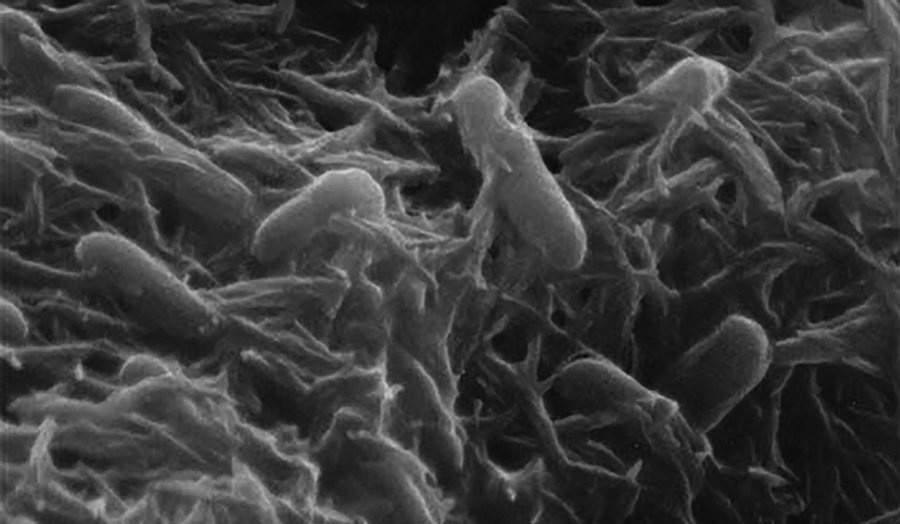

Electrogenic microbes settle spontaneously on the electrodes of MFCs, forming biofilms on their surface. Here the microbial colonies break down impurities dissolved in wastewater to convert this metabolic energy into useful electricity. While a simple concept, practical considerations need to be overcome to translate the project into a viable solution for the modern world’s energy needs. A single MFC can only produce a maximum voltage of 0.5 V and several MFCs have to be connected to achieve higher voltages.

In 2018, Fischer and his collaborators published a study describing the construction of a 12-litre MFC stack made of 12 connected MFC units. The 12-unit stack, assembled from four triple MFC modules, was able to charge three polymer lithium batteries at once. The investigation of this setup acted as a first significant milestone towards scaling up MFCs for wastewater-treatment-based electricity generation. The most significant step towards this target to date was taken with the publication of another study in 2021 by Fischer and his team in which they reported their successful design of a 1,000-litre MFC from 64 MFC units that could generate electricity while purifying wastewater. The interdisciplinary work and persistence of Fischer’s team has been instrumental in constructing the scale-up reactor and its use in the last few years, especially when considering that the researchers started their venture by originally designing small prototype reactors that ranged from just 20 to 250 ml.

Scaling up: a success story

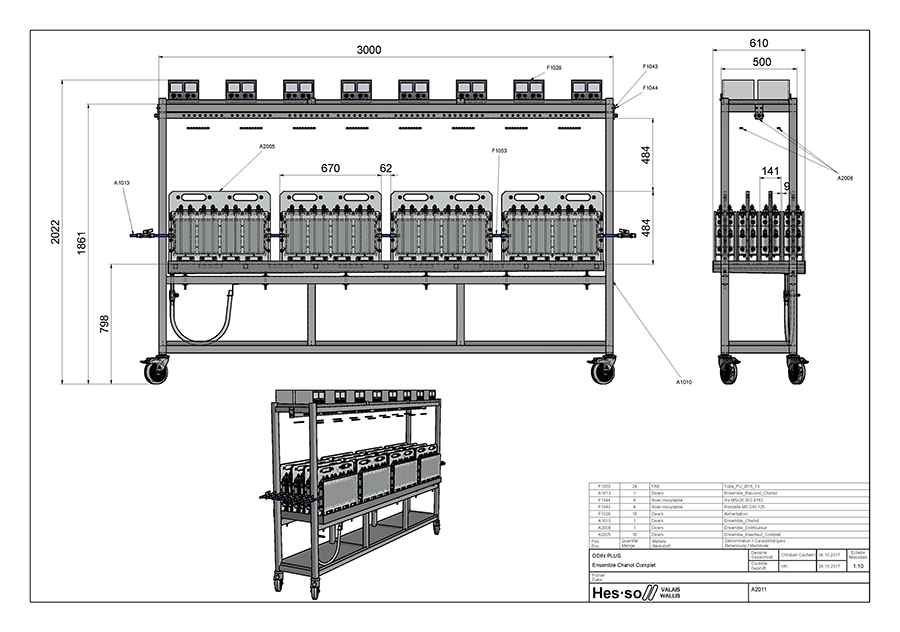

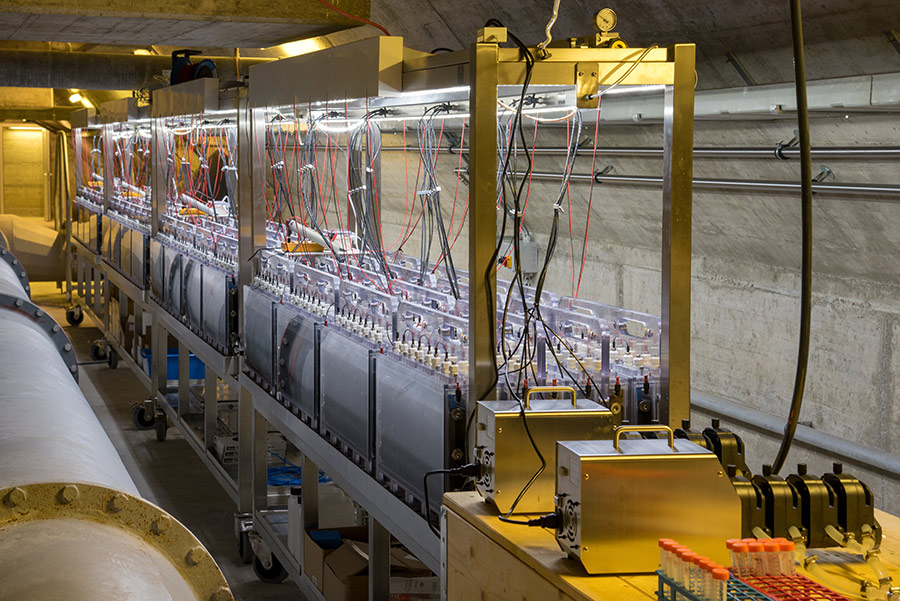

The 2021 study outlines how the team overcame these challenges, to build the 1000-litre MFC in the underground facility of a wastewater treatment plant in Sion, Switzerland. During the planning stage that preceded the construction of the 12m-long reactor, the researchers employed state-of-the-art computer aided design. Previous experience with smaller units helped the team to foresee many of the complications that could affect the efficiency and reliability of stacked MFCs. One difficulty to overcome was the decline in power generation due to the progressive drop in fuel availability once the wastewater becomes purified. Despite the technical challenges, the project was a success, with the 1000-litre MFC producing 0.015 kWh/m3 of electricity, with peaks of 0.060 kWh/m3.

The 1000-litre MFC was capable of both generating bioelectricity and purifying wastewater to legal requirements.

The microbial species present were capable of both generating bioelectricity and purifying wastewater to legal requirements, removing up to 48% of ammonia and 65% of the organic micropollutants. The system operated with energy efficiency of 5.8–12.1%, the highest achieved so far among MFCs employed in wastewater facilities. It is also important to point out that the system was able to run all year round, even when the temperature of the sewage dropped during the winter months.

Future perspectives

Despite its rather large dimension, the 1000-litre reactor is still only suited for smaller municipalities and would not meet the energy demands of wastewater treatment plants in larger cities. Some challenges remain to be overcome before MFCs can be built and operated at even larger scales. One of these is the higher costs associated with the extra materials needed for the construction of bigger reactors.

Another important goal would be to find ways of achieving higher rates of power generation. The current average power of 0.015 kWh/m3 is certainly helpful for the purpose of saving energy in the operation of wastewater plants but falls short of completely covering the power requirements of large wastewater treatment facilities. Fischer’s team is currently investigating how further improvements in design and the use of state-of-the-art technology could boost power production, with a view to enabling MFCs to completely cover the output of larger municipalities’ wastewater plants all year round.

What attracted you to your current research field and what excites you most when you go into the lab?

I heard about H Peter Bennetto’s work on biobatteries in the 1990s and thought it lent itself to further student research projects so we started to work with students in the field. It appeared to me to be a very open and versatile field to go into, that can be extended to many new applications. Today, we find pleasure not just in scaling up but also in discovering how biofilms function in an electrotechnical environment and combine even metagenomic tools to learn more about this promising concept.

How do you plan to research the remaining challenges of scale, and what further steps are necessary before your system could be adopted by industry?

We plan to construct both larger and smaller reactors. The aim is to collaborate with experts from many fields to continue our efforts to develop efficient reactors.

To what extent have you collaborated with the wastewater industry or industry regulators in your work so far?

We work with our partner plant in particular, and have connections today to many possible users in Switzerland and other countries.

Can you tell us about some of the wider applications of microbial fuel cells?

The concept of the microbial fuel cells offers many variations for diverse applications. These comprise their use as sensors, for example for pollutant detection or biotechnological processing. It is also of interest to bio-photovoltaics, fuels, chemicals, and fertilisers.